vertical shaft impact

crusher (sand crusher, crusher for produce sand)

vertical shaft impact

crusher (sand crusher, crusher for produce sand)

vertical shaft impact

crusher (sand crusher, crusher for produce sand)

vertical shaft impact

crusher (sand crusher, crusher for produce sand)

The vertical shaft impact crusher is the most advanced sand manufacturer in the world at present time, it may be divided into RX series granulator and SX series VSI crusher based on application. RX series granulator is used for round out angle of aggregate to improve shape of grain; SX series VSI crusher is used for crushing basalt, pebble, andseite, granite etc into manufactured sand by dry method. Here mainly introduce PEBRAS SX series VSI crusher.

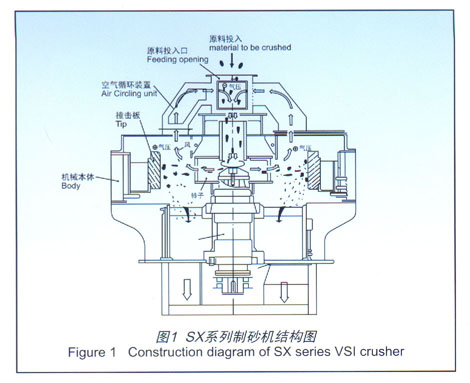

SX series VSI crusher consists of body, feeding tube, impacting plate, vertical shaft with rotor and motor(figure1)

The impacting plate is made from special high-Cr cast iron with high wearing property, fastening without bolts, easier replacing.

Equipped with air circling unit reducing dust discharging

The rotor fitted with wearing pad to prolong service life, to reduce quantity of damageable parts and to reduce running cost.

The high speed rotor is balanced to realize lower noise and lower vibration.

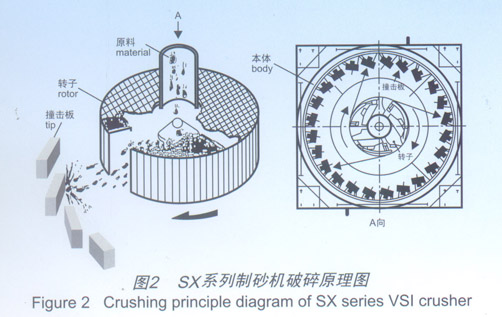

The material to be crushed is fed into machine from the feed opening of top, and fall down onto the central section of rotor rotating with high speed. Then it is thrown out with high speed by the strong centrifugal force of rotor, colliding with the impacting plate and crushed. The installed impacting plate shall be colliding with material to be crushed in right angle giving full play of excellent crushing performance. The manufactured sand with proper size is discharging out below the machine.

Excellent crushing performance

Low running cost

Less damageable parts

Long service life of damageable parts (made from special high-Cr cast iron or hard alloy)

Impacting plate may be adjusted and up side-down remounted, so, the productivity higher.

Easily replacing of damageable parts

Environment friendly

Lower noise and lower vibration

Less dust discharging out

|

Type |

Feeding size max. (mm) |

OD of rotor (mm) |

Speed of rotor (m/s) |

Power of motor (kw) |

Output (ton/h) |

|

700SX |

20 x 30 x 35 |

740 |

60 |

55 |

27 |

|

75 |

44 |

||||

|

90 |

57 |

||||

|

70 |

75 |

28 |

|||

|

90 |

38 |

||||

|

900SX |

20 x 30 x 35 |

890 |

60 |

110 |

69 |

|

125 |

82 |

||||

|

132 |

88 |

||||

|

70 |

110 |

45 |

|||

|

125 |

55 |

||||

|

132 |

60 |

||||

|

1000SX |

25 x 35 x 45 |

1040 |

60 |

185 |

102 |

|

200 |

111 |

||||

|

220 |

128 |

||||

|

70 |

200 |

67 |

|||

|

220 |

80 |

||||

|

1200SX |

25 x 35 x 45 |

1235 |

60 |

250 |

131 |

|

280 |

157 |

||||

|

315 |

188 |

||||

|

70 |

250 |

76 |

|||

|

280 |

95 |

||||

|

315 |

119 |

Note: the value shown on above table is based on bulk density of 1.6t/m3 and taking andesite as example, the actual production may depend on actual material, moisture content etc. In view of ooutput and service life of damageable parts, it is better to feed material less than 15mm (width size).

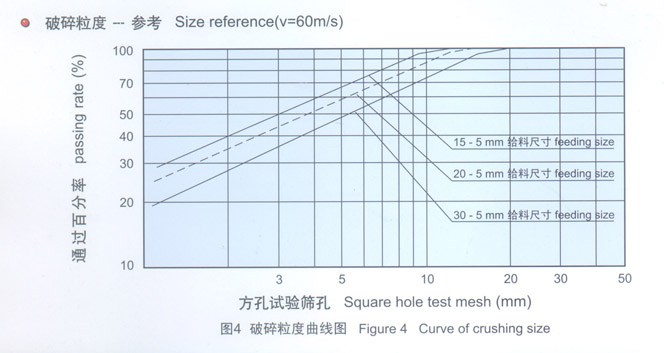

|

Type |

Feeding (t/h) |

Size (mm) |

Output (t/h) |

|

700SX |

57 |

30-5 |

28 |

|

20-5 |

34 |

||

|

15-5 |

38 |

||

|

900SX |

88 |

30-5 |

43 |

|

20-5 |

52 |

||

|

15-5 |

59 |

||

|

1000SX |

128 |

30-5 |

63 |

|

20-5 |

76 |

||

|

15-5 |

86 |

||

|

1200SX |

188 |

30-5 |

92 |

|

20-5 |

111 |

||

|

15-5 |

126 |

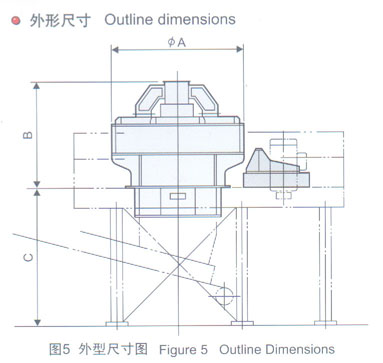

outline dimensions:

|

Type |

A |

B |

C |

|

700SX |

2240 mm |

1845 mm |

2400 mm |

|

900SX |

2240 mm |

1845 mm |

2400 mm |

|

1000SX |

2880 mm |

2450 mm |

2900 mm |

|

1200SX |

2880 mm |

2450 mm |

2900 mm |

weight of the main parts:

|

name |

700SX |

900SX |

1000SX |

1200SX |

|

Body assembly |

7600 kgs |

7900 kgs |

12700 kgs |

13300 kgs |

|

Upper hood of body |

1240 kgs |

1340 kgs |

1970 kgs |

2070 kgs |

|

Rotor |

400 kgs |

560 kgs |

970 kgs |

1220 kgs |

|

Impacting parts |

2000 kgs |

2100 kgs |

4200 kgs |

4500 kgs |