symons cone crusher, symons crusher

symons cone crusher, symons crusher

symons cone crusher, symons crusher

symons cone crusher, symons crusher

SYMONS Cone Crusher has the following characteristics

IT HAS BIGGER CRUSHING CAPACITY AND BIGGER PRODUCING CAPACITY

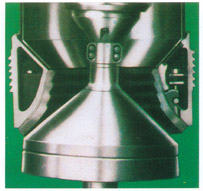

1. Seto Cone Crushers will supply greater crushing force for you .The length of the force arm designed for the Seto cone crusher exceeds all other cone crushers available today. The longer the force arm, the greater the moment of crushing impact. The Seto long force arm represented by the main shaft, provides lower eccentric bearing loads, lower bearing temperature and increased bearing life.

2. Largest head displacement provides greater producing capacity. With its large throw and complimentary head angle, has a displacement volume unmatched by any other cone crusher.

3. This combination of superior crushing force and free flow of material provides higher crusher efficiency which means lower power consumption.

IT HAS TWO TYPES OF CRUSHING CAVITY CONSTRUCTION, IT IS FIT FOR THE PRODUCT WHOSE GRAIN SIZE ARE REQUIRED IN A LARGE SCOPE AND THE GRAIN SIZE IS ALSO UNIFORM.

1. Seto standard crushers may be applied to large or small operations for single reduction, or as a primary or secondary crusher ahead of short head machines. They may be furnished with fine medium coarse or extra coarse cavities to meet variations in size of feed and end product.

2. Seto short head crushers have a steeper head angle and a more parallel crushing cavity than standard units. They are designed to take a small feed and are intended to make a smaller product. Product range is from less than 5mm to about 25mm in both open and closed circuits.

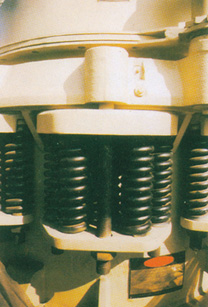

THE SETO SPRING RELEASE SYSTEM WILL PROVIDE SAFE AND EFFECTIVE OVERLOAD PROTECTION.

1. The Seto spring release system acts as an overload protection system that allows tramp iron to pass through the crushing cavity without damage to the crusher.

2. The Seto spring release system generates more opposing force than other cone crushers, so the crushing force is even greater. More crushing force means more productivity.

HYDRAULIC CONTROLS PROVIDE FAST SETTING CHANGES

AND SIMPLIFY CLEARING.

1.A portable hydraulic power unit is connected to the hydraulic cleaning jack

circuit. With the power unit activated, the cylinder rams raise the adjustment

ring bowl and liner assembly away from the main frame, providing increased

clearance in the crushing cavity.

2.Hydraulic Setting - setting adjustment are made quickly and simple by

hydraulic controls using two levers mounted on the control console. All operator

controls can be mounted on a portable remote control console or can be located

in a control room for operator convenience.

A COMPLETE LUBRICATION SYSTEM.

1.We have a long history of product lubrication station, We have lubrication

high and low pressure lubrication cooler oil filter and so on, It is mainly used

in circle system of cement, metallurgy, rolling, mine, heavy industry.

2.The quality of the lubrication equipment has been perfecting with the

technological development. The internal face is painted with the aluminum and

the external face is painted with the plastic after the internal and external

face are pained with the sand, The pipe lines are phosphorous after it is acided,

all the valves are new types of copper valves, the connector are changed to the

plane and thread seal.

3.In order to suit the different environment temperature, we have developed

electric cooler with the advanced cooling technology. It can not restricted by

the operated environment. The effect have been enhanced about one time than

water cooler and old electric cooler.

Seto cone crusher capacity charts are developed for use as an application tool to properly utilize the machine's capabilities. The crusher is one component of the circuit. As such, its performance is in part dependent on the proper selection and operation of feeders v conveyors screens supporting structure electric motors, drive components and surge bins. The following factors will enhance crusher capacity and performance.

1. Proper selection of crushing chamber for material to be crushed.

2. A feed grading contains proper distribution of the particle sizes and controls the feed rate.

3. Proper feed distribution 360< around the crushing chamber.

4. Adequate crusher discharge space and discharge conveyor sized to carry maximum crusher capacity.

5. Properly sized scalping and closed circuit screens.

6. Automatic control.

The following factors will reduce the crusher capacity and performance;

1. Sticky material in crusher feed or excessive feed moisture.

2. Fines in crusher feed (smaller than crusher setting) exceeding 10% of crusher capacity.

3. Feed segregation in crusher cavity or improper feed distribution around circumference of crushing cavity.

4. Lack of feed control.

5. Inefficient use of recommended connected horsepower.

6. Insufficient crusher discharge area of insufficient conveyor capacity.

7. Insufficient scalper and closed circuit screen capacities.

8. Operation of crusher at less than recommended full load countershaft speed.

STANDARD CONE CRUSHER CAPACITY CHART - OPEN CIRCUIT

STANDARD CONE CRUSHER CAPACITY CHART - CLOSED CIRCUIT

SHORT HEAD CONE CRUSHER CAPACITY CHART - OPEN CIRCUIT

SHORT HEAD CONE CRUSHER CAPACITY CHART - CLOSED CIRCUIT